- spécifications du produit

- conditionnement

- demander un devis

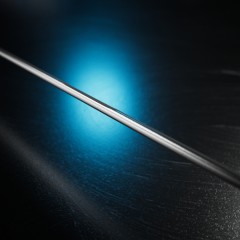

This nickel based alloy offers superior wear protection, retaining its hardness up to 600ºC (1000ºF) with significant resistance to oxidation.

Not required

NiCrBSi 4 TIG offers outstanding metallurgical and physical properties making them ideally suited to solving wear mechanisms such as abrasion, erosion, corrosion and high-temperatures encountered in service.

NiCrBSi 4 TIG offers outstanding metallurgical and physical properties making them ideally suited to solving wear mechanisms such as abrasion, erosion, corrosion and high-temperatures encountered in service.

This nickel based alloy offers superior wear protection, retaining its hardness up to 600ºC (1000ºF) with significant resistance to oxidation.

UNS N99644, DELORO 40 Alloy, Colmonoy 4

Aircraft gas turbines, steam turbine powerplants, turbochargers and valves in reciprocating engines, prosthetic devices, heat treating equipment, pollution control equipment, coal gasification and liquefaction systems, and components in pulp and paper mills.

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Hardness |

|---|---|---|---|---|

| As Welded | 40 HRc |