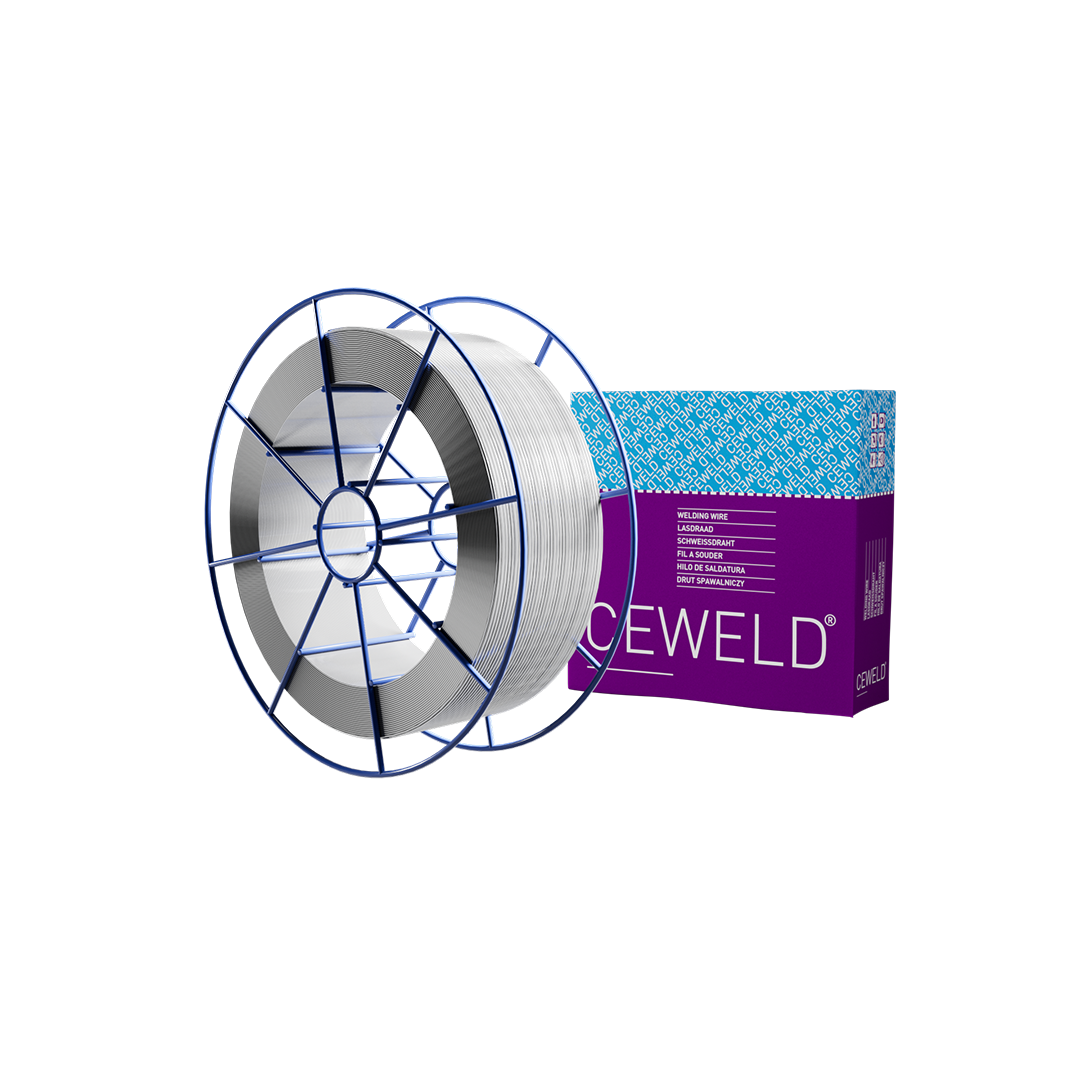

- PRODUCT SPECIFICATIONS

- PACKAGING

- Ask quotation

CEWELD® 430 LNbTi was developed for the automotive industry and is used in the manufacture of exhaust systems and catalytic converters. This wire should be used when good resistance to corrosion and thermal fatigue is required.

Suitable for use with stabilized ferritic stainless steels, austenitic stainless steels, and in both homogeneous and heterogeneous sheet configurations (sheets of different grades welded together).

CEWELD® 430 LNbTi was developed for the automotive industry and is used in the manufacture of exhaust systems and catalytic converters. This wire should be used when good resistance to corrosion and thermal fatigue is required.

Suitable for use with stabilized ferritic stainless steels, austenitic stainless steels, and in both homogeneous and heterogeneous sheet configurations (sheets of different grades welded together).

Stabilization with niobium and titanium gives CEWELD® 430 LNbTi the advantages of these two ferritic microstructure stabilizers: Titanium minimizes grain growth in the weld zones (WM) by precipitating titanium nitride (TiN) in the still-molten metal in these zones, thus preventing the risk of embrittlement that can sometimes occur with very thick welds (> 3 mm of the sheet being welded). Niobium retains the remaining carbon and nitrogen by transferring 85 to 95% of the carbon in the welding arc under all standard welding conditions, thereby preventing the risk of intergranular corrosion in the weld metal.

1.4509, AISI 441, UNS-Nummer: S43940

1.4000, 1.4002, 1.4016, 1.4057, 1.4740, 1.4742, 1.4057, 1.4059, 1.4741, 1.4509, 1.4510, 1.4511, 1.4512, 1.4520, 1.4712, 1.4713, 1.4724,

X7Cr14, X12Cr13, X17CrNi16-2, X6Cr13, X6CrAl13, X6Cr17, X17CrNi16-2, X2CrTiNb18, X3CrTi17, X3CrNb17, X2CrTi12, X2CrTi17, X10CrSi6, X10CrAlSi7, X10CrAlSi13, X10CrAlSi18

UNS S40300, S40500, S40900, S41000, S42900, S43000, S43035, S43036, S43100, S44200

AISI 403, 405, 409, 410, 429, 430, 430Cb, 430Ti, 439, 431, 442

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Hardness |

|---|---|---|---|---|

| As Welded | 310 | 450 | 25 | 140 HRc |