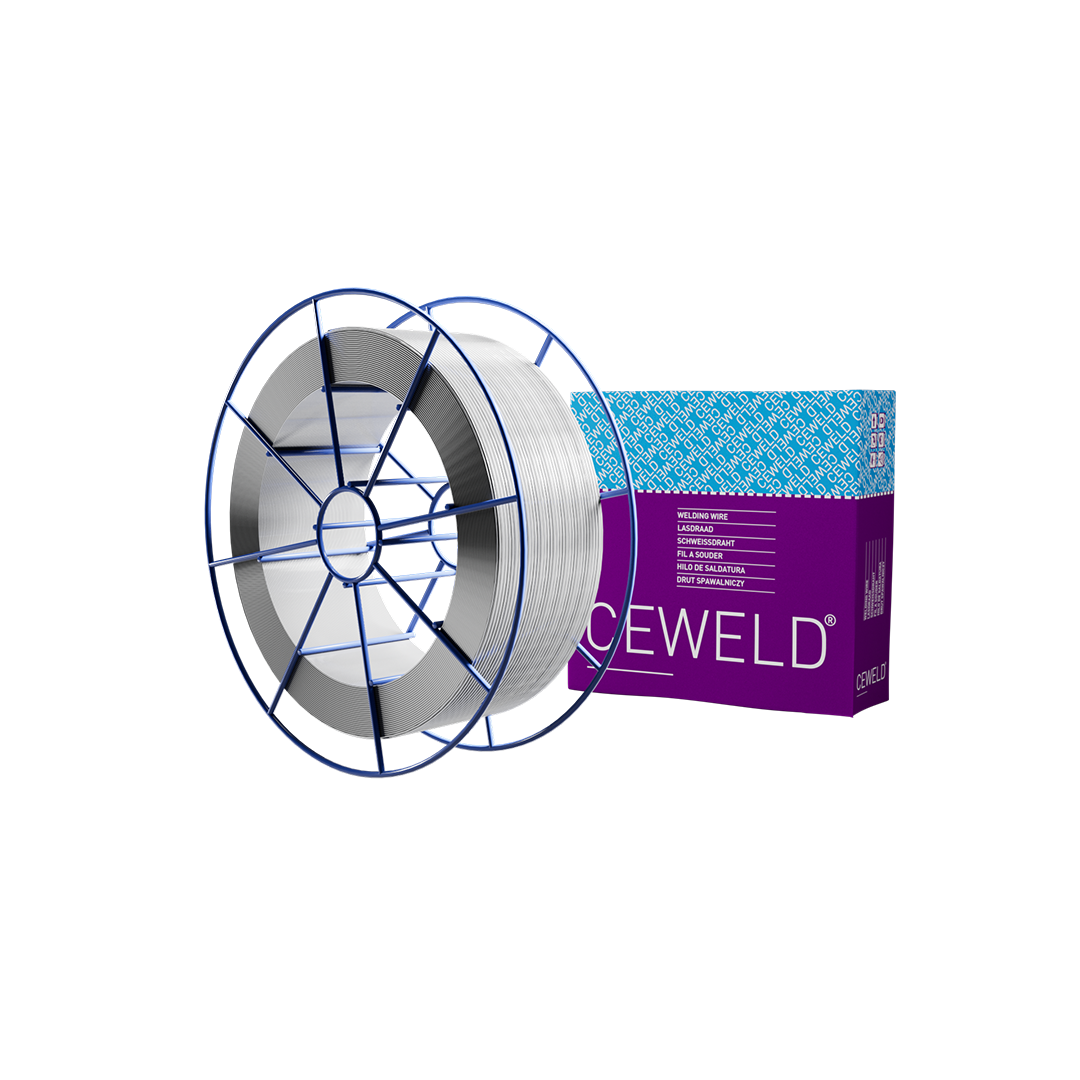

- PRODUCT SPECIFICATIONS

- PACKAGING

- Ask quotation

CEWELD® 430 can be used for various build-up welding and joining applications. Sealing surfaces in steam, gas, and water fittings at operating temperatures up to +450°C.

CEWELD® 430 can be used for various build-up welding and joining applications. Sealing surfaces in steam, gas, and water fittings at operating temperatures up to +450°C.

CEWELD® 430 offers excellent weldability, good corrosion resistance and high temperature resistance. Its Brinell hardness is approximately 225 HB, depending on the base material and the number of layers.

CEWELD® 430 exhibits scale resistance of up to 950°C in air, oxidising combustion gases and sulfur-containing combustion gases at higher temperatures. It is preferable to weld with a pulsed arc and to preheat larger wall thicknesses to between 150 and 300°C. Ensure low heat input.

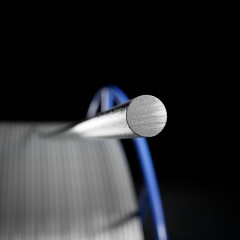

Ferritic 17 % Chrome steel,

1.4000, 1.4002, 1.4016, 1.4057, 1.4740, 1.4742, 1.4057, 1.4059, 1.4741, 1.4509, 1.4510, 1.4511, 1.4512, 1.4520, 1.4712, 1.4713, 1.4724,

X7Cr14, X12Cr13, X17CrNi16-2, X6Cr13, X6CrAl13, X6Cr17, X17CrNi16-2, X2CrTiNb18, X3CrTi17, X3CrNb17, X2CrTi12, X2CrTi17, X10CrSi6, X10CrAlSi7, X10CrAlSi13, X10CrAlSi18

UNS S40300, S40500, S40900, S41000, S42900, S43000, S43035, S43036, S43100, S44200

AISI 403, 405, 409, 410, 429, 430, 430Cb, 430Ti, 439, 431, 442

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Hardness |

|---|---|---|---|---|

| As Welded | 320 | 460 | 21 | HRc |