- PRODUCT SPECIFICATIONS

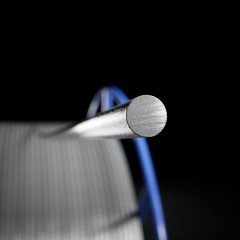

- PACKAGING

- Ask quotation

CEWELD® 410 is used to overlay carbon and low-alloy steels to provide corrosion, erosion and abrasion resistance. CEWELD® 410 is harder and is used in valve seats to improve galling resistance. To obtain adequate ductility, preheating and post-weld heat treatment are normally required.

CEWELD® 410 is used to overlay carbon and low-alloy steels to provide corrosion, erosion and abrasion resistance. CEWELD® 410 is harder and is used in valve seats to improve galling resistance. To obtain adequate ductility, preheating and post-weld heat treatment are normally required.

CEWELD® 410 is a heat-treatable martensitic stainless steel. It has a nominal weld metal composition of 13% chromium. These air-hardenable weld deposits can normally be heat-treated after welding for service temperatures of up to 450°C. =(+)

Ferritic 13 % Chrome steel,

1.4000, 1.4001, 1.4002, 1.4003, 1.4006, 1.4008, 1.4021, 1.4024,

X6Cr13, X6CrAl13, X10Cr13, X15Cr13, X20Cr13, G-X10Cr13, X7Cr14, X6CrAl13, X 20Cr13, X15Cr13

AISI 410, 420

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Hardness |

|---|---|---|---|---|

| As Welded | 420 | 650 | 18 | 30 HRc |